PT-11 Construction Begins

November 15, 2009

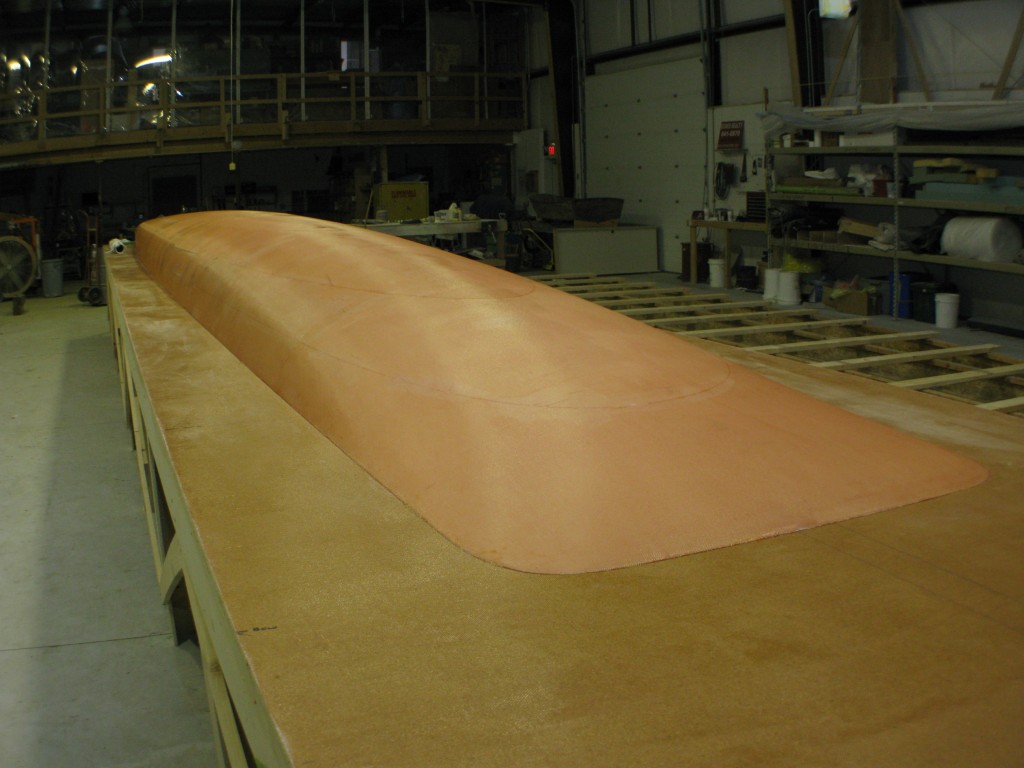

Construction of the project began in earnest in the second half of November. We began with the ama tooling pictured below.

The first Challenge

November 17, 2009

The first challenge was building the tables that were to act as building

floors for our CNC machined foam ama plug, which is pictured below. The

next parts tackled were the beams molds and the main hull tool.

Beam Building

November 22, 2009

The beam plugs are ready for molding.

MOld Stations

November 23, 2009

Scott assembles computer lofted and CNC cut mold stations.

Thanksgiving Break

November 30, 2009

On November 31st, just after our Thanksgiving break the hull molds were erected with a few ribbands supporting them.

Plug Completed

January 13, 2010

The plug was complete and ready to build on.

THERMO FORMED CORE

January 28, 2010

The core was thermo formed into our female molds on January 28th.

HAppy Valentines Day

February 14, 2010

Happy Valentine’s Day! As we pull the final ama halves from the tools,

it was love at first site! Scott and ‘Henri easily handle the 160# ama

half.

A few days later, Scott trimmed some carbon while laminating the ama inner skins.

Deck is tooled!

April 25, 2010

The deck was tooled as 3 separate components. the fore deck, the house

back bulkhead, and the cockpit. We did this to save space in the shop

and to aid in construction. Redundancy of laminate when joining parts

and the parasitic weight that comes with it was avoided by carefully

tapered laminates on each of the components.

First Assembly - Upside down no less

April 26, 2010

The ama halves and beams were fit to the main hull in order to bond the

beam sockets. The outboard sides of the amas are not bonded until a post

cure is complete, ensuring the inner skin and structure is fully post

cured.

Rudder core machined & Aft beam sockets laminated in place

April 30, 2010

The rudder core is machined prior to inserting into the female tool.

There is a significant uni carbon strap over the socket holding the aft beam in place between the transom and forward ring frame. This is no place to skimp on material..

Transom with the traveler beam!

The transom is now complete. The sugar scoop edge is capped the sole is taped and the traveler beam is glued and taped in place. Once again Tim Chisholm has done an incredible job of boat building. And yes - we will trim the exhaust pipe.

“THREE LITTLE BIRDS” The PT 11/1 has a name

Three Little Birds, is a great song by a master musician. We here at

ACC are pleased that the owner thinks so much of his project as to

equate our work with such a prestigious piece of musical history. I am

sure that our version of Three Little Birds will live up to it’s big

name!

Dagger Laminated in CNC Cut Female Mold

Louie and Doc made a nice job of laminating the first half of the dagger board. Note the carefully tapered layers of carbon.

Ready to roll…

3 LITTLE BIRDS is primed and ready to go upright for final assembly and systems installation.

OVER SHE GOES!

The main hull goes over with her structure and interior partioins in place and finish primed.

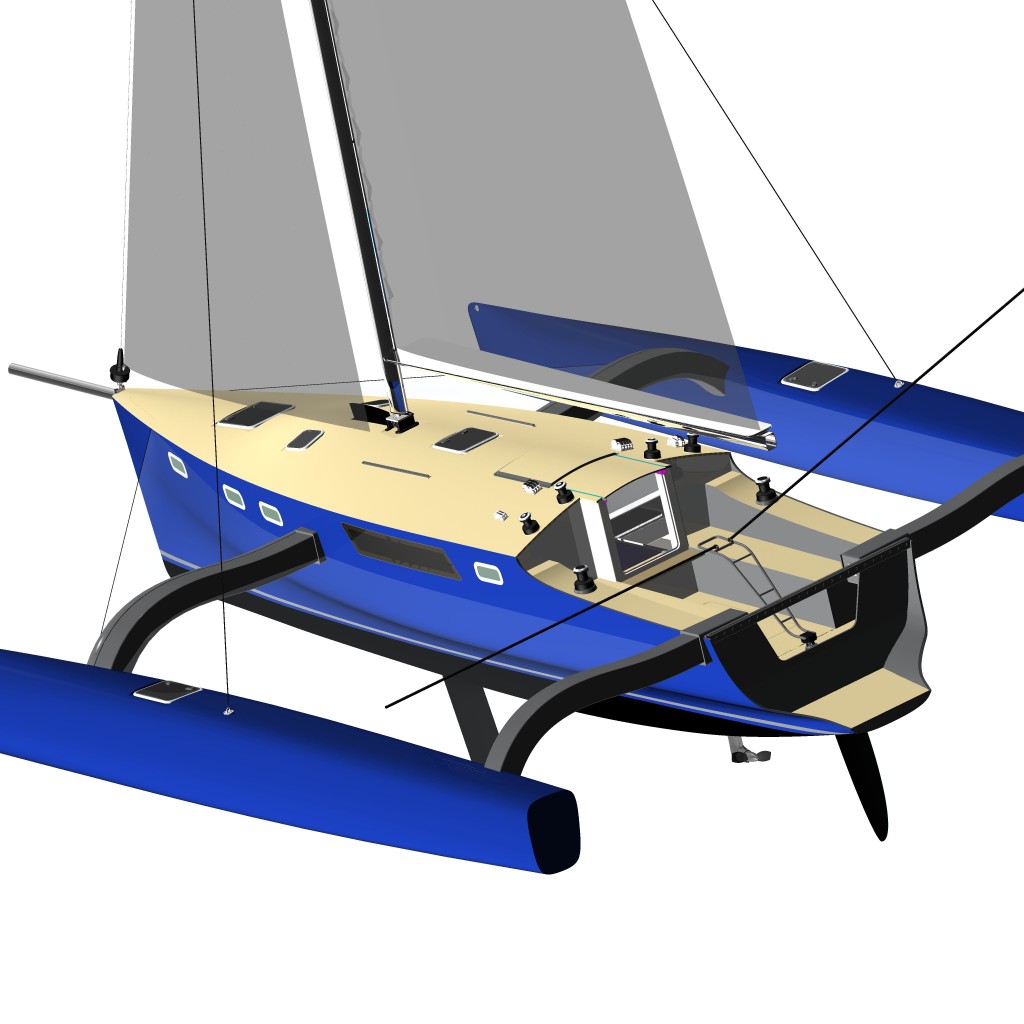

A view of the finished boat

June 5, 2010

Dave Walworth has provided some renderings of the nearly finished 3-D model. This one is my personal favorite. The model is growing as the design nears completion of all the details. Not only is this a pretty picture it is also an exact duplicate of the actual boat / or more to the point the boat is an exact duplicate of the model. The interior structure, systems, and deck gear are all part of the model and we can take a 3-D section anywhere to create drawings and CNC tool paths for building or modifying any component or system of the boat.

Nearly ready to fly

July 22, 2010

It has been a while since we have added a new post. Lots has happened since our last post. The interior is finish painted and systems are nearing completion. Now we are ready to finish paint her for an August launching .. For now until we get the gloss on her here are the first shots of “Three Little Birds” out of the building shed.. By the way - The door is 30′ wide!

Update on the PT11 trimaran “Three Little Birds”

January 23, 2012

This winter we have added a very unique anchor roller to the Birds. The anchor roller is set “normal” to the sheer near the bow. Being a multi hull anchoring always includes a bridle off of the ama. So the fair lead for the anchor rode is just what you see. It comes more or less perpendicular off of the boat. We also added carbon tracks for the bikini nets, and then a repaint of the whole bow area including some more refinement of the stem.. She is a sweet boat!

J111 rudders and Custom Trimaran Parts

February 22, 2012

Aquidneck Custom is now supplying the entire rudder package to the J111 program. This includes our female molded carbon rudder post.

The PT11, Three Little Birds, with her new bow roller finished and ready to anchor!